What is your experience with Totem beams and construction system? Which part is most difficult? What kind of things are you missing and changes you would like to see.

If you are having problems cutting grooves in the 3mm steel rods to fit E-clips, try using Modelcraft 10434 shaft collars. ID 3.05mm OD 8mm Thickness 5mm and are supplied with M3 grub screws.

I checked them out here.

I have long thought how to make a small tool to make such grooves. Eventually I will come up with something. Using some 3D printed tool parts maybe.

1 Like

If using the 10434 shaft collars, allow 4mm extra length to the steel bar per collar (ie 8mm if using 2). The grub screw uses the same allen key as supplied in the MOTOR COUPLER 3-3 SET supplied by Totemmaker. Another possible idea would to use 3mm brass bar which is widely available. This will be softer and should only be used in low strength/wear applications.

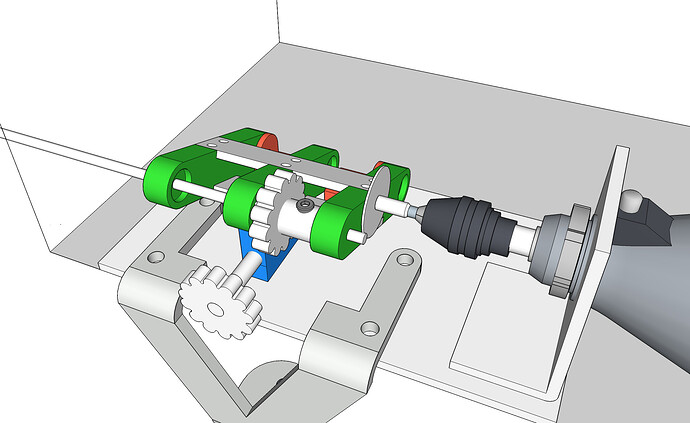

Some time ago we were designing on a groove-cutter for 3mm steel rods. Using Dremel and similar tools. But we haven’t done more for a while.

The idea was that the 2 white wheels is operated to lead the 3mm rod carefully inwards, and to rotate the rod slowly to make the groove all around the rod.

It would be nice to make something, and present as a product. So much other things have been needed before this…